Máy đo cặn sắt mỡ bôi trơn SDM-72 New Cosmos SDM-73 New Cosmos

Máy đo cặn sắt mỡ bôi trơn SDM-72 New Cosmos SDM-73 New Cosmos

-

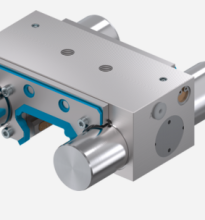

SDM-72 New Cosmos

-

Liên hệ

-

237

- Thông tin sản phẩm

- Bình luận

NEW COSMOS Japan

Máy đo cặn sắt mỡ bôi trơn SDM-72 New Cosmos SDM-73 New Cosmos

Portable steel dust meter

to check the wear condition of bearings in ultra-low to high speed rotating machinery

Model: SDM-72 /SDM-73

With the SDM-72 SDM-73 you are able to diagnose the bearing condition, even long before wear-induced vibration becomes detectable, by measuring the amount of steel dust in oil around the bearing.

Within 3 seconds the meter gives you a readout of the ferro magnetics particles in the oil in parts per million ppm. No need to send your sample to a laboratory for analyses any longer. You now get on the spot direct measurement.

The meter can be used in any rotating equipment application such as robots, wind turbines, elevators etc. etc. Preventive maintenance is key for increase in uptime of your equipment.

-

Features

- Best suited to diagnose low-speed rotation machinery and variable-speed rotating machinery which are hard to be diagnosed by vibration indicators

- Battery-operated and convenient to carry or use on-site

- Simple operation without requiring special knowledge

- Equipped with auto-zero function

- Able to diagnose with only a small amount of grease/oil sample

Specification:

Measuring Principle

The measuring principle of the magnetic balance electromagnetic induction method is shown in the illustration below, the magnetic circuit sensor is composed of an exciter coil connected to the both sides of the detection coil, the magnetic field generated by both exciter coils are blanketed in the vicinity of the center detection coil.

Normally, the center detection coil does not generate an induction voltage, on the other hand when the sampled oil containing iron particles is inserted into the exciter coil, the magnetic field is offset by the magnetic permeability variation, and an induction voltage is generated in the detection coil The induction voltage can measure the concentration of the iron particles in the sampled oil.

Applications

- Pump/Motor

- Mixer

- Fan/Blower/Compressor

- Cooling tower/Air fin cooler

- Rotary Drying Oven

- Paper-making machine

- Mill/Crasher

- Rolling Machine

- Conveyor

- Crane/Lift

- Earth-moving machine

- Transporting machine

- Elevator

- Escalator/Moving walk

- Multistory parking lot

Usage Instructions

Maintenance and calibration :

► We also have calibration certificate attached ( optional )

► Please re-calibrate after use for a certain period through our purchase store.