Hệ thống hút ẩm và sấy khô DP - DRY PACK Eisbaer

0944911836 Ms. Duyên

0972835740 Ms. Hà

0385097045 Mr. Hiếu

0392468875 Ms. Anh

0707602728 Ms. Vân

Hệ thống hút ẩm và sấy khô DP - DRY PACK Eisbaer

Hệ thống hút ẩm và sấy khô DP - DRY PACK Eisbaer

-

Liên hệ

-

822

- Thông tin sản phẩm

- Bình luận

Hệ thống hút ẩm và sấy khô DP - DRY PACK Eisbaer

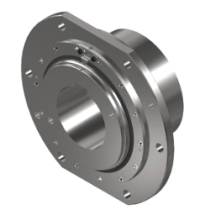

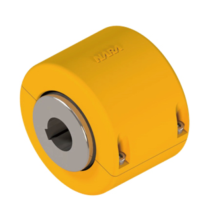

With the Drypack you are deciding for a system in which mold dehumidification and material drying are combined.

This means:

- Lower installation costs

- Lower space requirement

- Lower energy consumption

Eisbär guarantees optimally dry material for your plastics processing and no condensation water on plastic parts or cooled molds.

ADVANTAGES

- Continuous dehumidification and as a result a constant dew point guarantee extremely well-dried material.

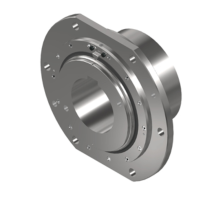

- High product quality and few moving parts signify low maintenance and service costs.

- The amount of dry air, process air heating power and hopper fill level optimally adjust to the material throughput of the production plant.

- Optimal energy saving is ensured by means of throughput control, Recusorb, dew point control, generously rated plate heat exchanger and continuous dehumidification.

- Dew point control as standard.

- Compact, space-saving design.

- System sizes (material throughput) completely open upwards.

- Integrated mold dehumidification.

- No condensation on cooled molds.

- Cleaner products without water marks.

Sản phẩm cùng loại